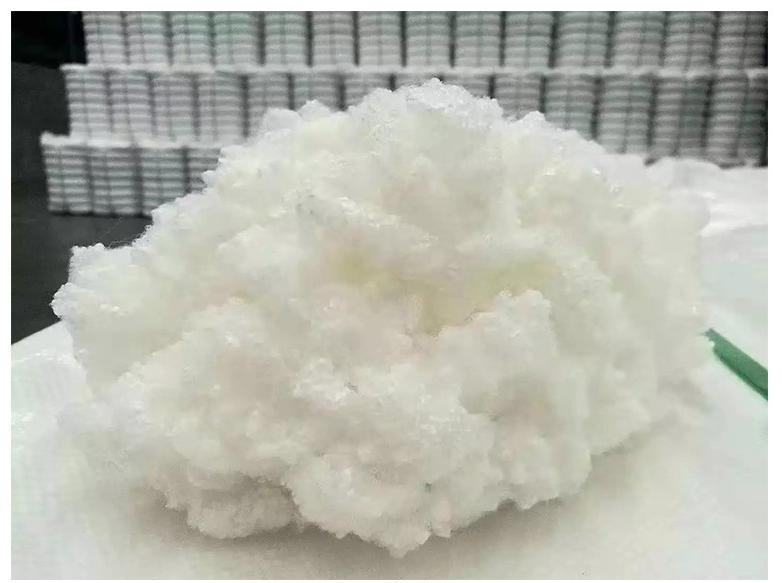

This is the most common method for producing rPET. Discarded plastic bottles are collected, sorted by color, thoroughly washed, and shredded into tiny flakes. These flakes are then melted, filtered, and extruded to form new recycled polyester filament yarn. This process significantly reduces the reliance on petroleum and diverts plastic waste from landfills and oceans.

The textile industry is undergoing a green revolution, and at the heart of this transformation is Recycled Polyester Fiber & Filament Yarn. As a high-performance material derived primarily from post-consumer plastic bottles, it offers a powerful solution to the environmental challenges of traditional textile production. This article delves deep into the world of rPET, exploring its manufacturing, undeniable benefits of recycled polyester filament yarn, and its growing dominance in the global market for sustainable textiles recycled polyester.

How is Recycled Polyester Fiber Made?

The journey of Recycled Polyester Fiber & Filament Yarn is a remarkable process of transformation. It begins with waste and ends with a high-quality textile material, showcasing a circular economy in action. Understanding this process is key to appreciating its value and performance.

From Bottle to Bale: The Mechanical Recycling Process

Chemical Recycling: A Game-Changer for Quality

Chemical recycling breaks down PET plastic into its base monomers, purifying them before repolymerizing them into new polyester. This method can handle a wider range of waste materials and produces a fiber that is virtually identical to virgin polyester in quality, opening up new possibilities for high-end applications.

Why Choose Recycled? The Compelling Advantages

Opting for Recycled Polyester Fiber & Filament Yarn is not just an environmental statement; it's a smart, strategic decision. The benefits of recycled polyester filament yarn extend across ecological, performance, and economic dimensions, making it a superior choice for forward-thinking brands and manufacturers.

Environmental Impact Reduction

Consumes up to 59% less energy and reduces carbon footprint by up to 32% compared to virgin polyester

Performance Excellence

Offers same durability, strength, and colorfastness as virgin polyester with versatile applications

Market Competitiveness

Meets growing consumer demand for sustainable products and enhances brand value

rPET Yarn vs Virgin Polyester: Breaking Down the Differences

When considering rPET yarn vs virgin polyester, it's crucial to look beyond the surface. While they share many functional characteristics, their origins and impacts are worlds apart.

| Aspect | Recycled Polyester (rPET) | Virgin Polyester |

| Raw Material | Post-consumer PET bottles | Crude oil (Petroleum) |

| Energy Consumption | Significantly lower | High |

| Carbon Footprint | Up to 32% lower | Substantially higher |

| Resource Depletion | Conserves petroleum resources | Depletes finite resources |

| Waste Management | Diverts plastic from landfills | Contributes to plastic waste |

| Performance | Equivalent in strength and durability | High strength and durability |

Choosing Reliable Recycled Polyester Yarn Suppliers

Partnering with the right recycled polyester yarn suppliers is critical to ensuring product quality, consistency, and the integrity of your sustainability claims.

Certifications and Transparency

Prioritize suppliers with Global Recycled Standard (GRS) or Recycled Claim Standard (RCS) certifications for verified recycled content and responsible practices.

Quality and Supply Chain

Choose suppliers with advanced technology, rigorous quality control, and robust global supply chains for consistent quality and reliable delivery.

Innovative Uses in Sustainable Textiles

The versatility of Recycled Polyester Fiber & Filament Yarn has fueled its adoption across countless sectors in sustainable textiles recycled polyester products.

Fashion and Apparel

From activewear to high fashion, rPET's moisture-wicking and durable properties make it ideal for sportswear, outdoor gear, and elegant clothing collections.

Home Furnishings

Used in soft, resilient carpets, blackout curtains, and durable upholstery fabrics for long-lasting performance and smaller ecological footprint.

Technical Textiles

Engineered for non-woven applications, geotextiles, and industrial filters, demonstrating functional strength in demanding environments.

FAQ

Is recycled polyester fabric safe and non-toxic?

Yes, high-quality Recycled Polyester Fiber & Filament Yarn is perfectly safe and non-toxic. The rigorous manufacturing process, which includes high-temperature melting and filtration, removes any impurities from the source materials. Furthermore, certified rPET from reputable recycled polyester yarn suppliers is often tested for harmful substances, meeting international safety standards for textiles.

Does recycled polyester shed microplastics?

Like all synthetic fibers, including virgin polyester, recycled polyester filament yarn can shed microfibers during washing. However, the industry is actively addressing this challenge through advanced fabric constructions, washing machine filters, and biodegradable fiber technologies. The environmental benefits of rPET in reducing waste and carbon emissions remain substantial.

Can recycled polyester be recycled again?

Technically, yes, but the practical infrastructure for closed-loop recycling of polyester textiles is still developing. The primary strength lies in transforming plastic bottle waste into high-value, durable textiles. Research into chemical recycling promises a future where polyester garments can be infinitely recycled back into new fibers.

How does the cost of recycled polyester compare to virgin?

The cost dynamic of rPET yarn vs virgin polyester has shifted significantly. While rPET was once more expensive, economies of scale, improved collection systems, and growing demand have made it highly competitive. The marketing value and brand enhancement from using sustainable material often provide a strong return on investment.